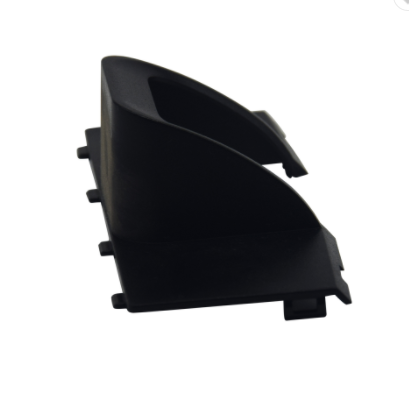

Customized ABS Derlin Nylon vacumm casting Plastic Rapid Prototype Service Manufacturing

- HRTS

- Shenzhen

- 3-7 working days

- 1000 Piece/Pieces per Month

Vacuum casting (also known as urethane casting) is an economical alternative to low-volume injection molding of plastic parts and can be used to closely simulate final molded parts or finished products. Generally, molds are made from silicone rubber and use CNC machining or SLA part as a master pattern. These molds duplicate intricate details and textures and give consistent finishes from one part to the next. You can get production-like results including mechanical traits, wall thickness, colors, and surface finishes.

Customized ABS Derlin Nylon vacumm casting Plastic Rapid Prototype Service Manufacturing

Services | Vacuum casting CNC Turning, CNC Milling, Laser Cutting, Bending, Spaning, Wire Cutting,3D Printing Servive |

Raw Material | Aluminum: 2000 series,6000 series,7075,5052 etc |

Stainlesss steel: SUS303,SUS304,SS316,SS316L,17-4PH etc | |

Steel: 1214L/1215/1045/4140/SCM440/40CrMo etc | |

Brass: 260, C360,H59,H60,H62,H63,H65,H68,H70,Bronze,Copper | |

Plastic: Acetal/POM/PA/Nylon/PC/PMMA PVC/PU/Acrylic/ABS/PTFE/PEEK etc | |

Work Table Size | 1200* 800* 500mm |

Surface Treatment | Anodize, Bead blasted, Silk Screen, PVD Plating, Zinc/Nickl /Chrome/Titanium Plating, Brushing, Painting, Powder Coated,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc |

Surface Roughness | Min Ra 0.2~3.2 |

File Format | IGS, STP, X-T |

Tolerance | 士 0.01mm (it depends) |

Software | ProE, Solidwork, UG, 3D Max |

Surface Treatment | Including sanding, sandblasting, mirror polishing, painting, printing, laser etching, anodizing, electroplating, chroming, powder coating, etc. |

MOQ | 1 PCS |

Lead Time | 3-5 Days |

Packaging | Carton Box Or Wooden Case |

Payment Terms | T/T |

Advantages Of Vacuum Casting

Low cost for silicone molds

Cast urethane parts are made of cheap molds, eliminating the need to invest in expensive and time-consuming metal tooling. It is a cost effective method for making high quality prototypes and low volumes of parts.Fast delivery

Up to 50 functional cast urethane parts can be produced in 10 to 15 days when you choose vacuum casting.A wide selection of materials

Casting resins materials range from soft and flexible to rigid and impact-resistant, as well as colored and clear.High precision and fine details

Vacuum casting provides end-use parts of high precision and fine details with production-level quality.Excellent surface finish

Urethane casting can provide better surface textures compared with CNC prototyping or 3D printing.Product show: